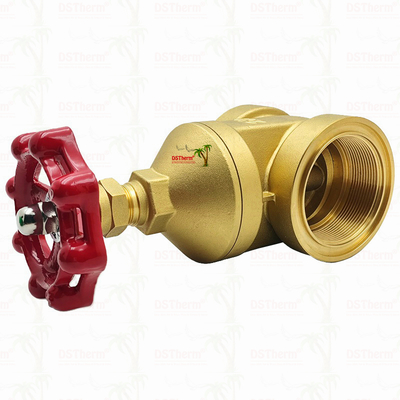

Specification

What is Gate Valve?

The Gate Valve is a shut-off valve that uses a vertically raised gate to fully open or close the pipeline fluid.

Feature

1.Higher pressure bearing capacity:

PN25 (≈Class 250), 25% higher pressure resistance than conventional PN16/P20 valves, suitable for medium and low pressure steam and high pressure water systems.

2.Wider size coverage:

Standard diameter ½"~4" (DN20-DN110), supports full-size customization, suitable for main pipelines and branch pipelines.

3.Material and certification:

Brass valve body: corrosion-resistant, antibacterial, passed international ISO standards (such as ISO 5208 sealing test), ensuring versatility and reliability.

4.Deep customization:

Special diameters, handwheel styles (such as anti-slip/labor-saving design), and brand logos (OEM requirements) can be customized.

Functions

- Reliable cut-off control: Fully open/full closed to isolate fluid, full-diameter design with almost zero flow resistance.

- Bidirectional seal: Both forward and reverse installation can block the medium (water, gas, oil, low-pressure steam).

- Quick opening and closing (manual): Adapt to customized handwheel for easy operation.

Application

1. HVAC: high-pressure hot water/steam main pipeline (≤PN25), refrigerant control system.

2. Industrial equipment: compressor high-pressure gas pipeline, hydraulic station oil circuit, boiler water inlet branch valve.

3. Building water: high-rise building water supply main pipeline (boosting system), fire pump room valve.

4. Customized projects: non-standard mechanical matching (such as marine equipment, special units), brand engineering logo (Logo customized valve).

Our Advantages

Performance upgrade: PN25 pressure + 4" diameter → Covers more stringent working conditions (high-pressure water/low-pressure steam).

Flexible customization: Full adaptation of size/handwheel/Logo → Solve the pain points of non-standard design and improve brand integration.

Brass cost performance: Within the pressure range, it is 30%~50% cheaper than stainless steel gate valves, and its corrosion resistance meets most water and gas scenarios.

Notes

Not suitable for strong acid/chloride ion corrosive media, fluids containing solid particles, and high-temperature steam >200℃ (limited by the sealing ring).

QC

· We promise to supply you high quality and durable goods for you.

· Our worker will check every accessory before hand-assembled.

· Our quality inspector will check every product one by one before packing.

· Regular checking on line from production in each workshop

Production step

1) purchasing the material and forged the semi-products .

2) processing the semi-products in workshop .

3) assembling the goods .

4) testing the sealing in pressure and checking quality of the goods

5) package

6) deliveing the goods on time.

Package

1) the package standard : standart export carton, box .

2) if customer has special requirement. it is available to provide the colorful package against the design of customer.

We Will Be Your Better Choice!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!