Specification

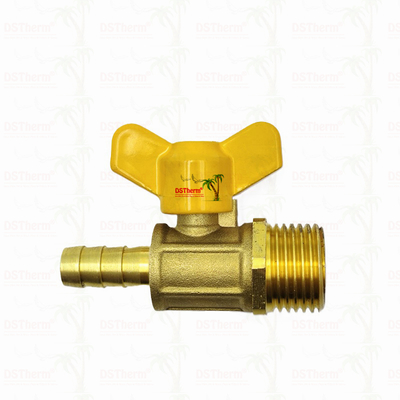

What is Gas Ball Valve?

A gas valve is a mechanical device installed in gas pipelines to control the flow, pressure, or direction of flammable gases (like natural gas, propane/LPG, or manufactured gas).

Design Drawing

Feature

1.Ultra-Low Pressure Design

Nominal Pressure: 0.022 MPa (22 kPa / 3.2 psi) – Optimized for low-pressure gas/fluid systems.

2.Multi-Medium Compatibility

Suitable for: Natural gas, Manufactured gas, LPG (Liquefied Petroleum Gas), and Water.

3.Robust Temperature Tolerance

Operating Range: -10°C to 80°C – Reliable performance in varied climates.

4.Standardized Threading

Thread Standard: ISO 228 (G-series) – Ensures global compatibility and leak-proof sealing.

5.Compact Butterfly Valve Structure

Flange Dimensions:

Bolt Hole Centres: 65.5 mm

Flange Diameter: Φ40 mm

Bolt Hole Diameter: Φ31 mm – Compact design for space-constrained installations.

Applications

1.Residential Gas Systems:

Low-pressure branch lines for cooktops, water heaters, or space heaters using natural gas/LPG.

2.Specialized Gas Distribution:

Manifolds for biogas, laboratory gas lines, or low-pressure industrial gas circuits.

3.Water/Low-Pressure Fluid Control:

Cooling systems, irrigation, or low-head water supply networks.

Usage Precautions

1.Pressure Limit Compliance

NEVER exceed 0.022 MPa – Risk of valve failure/leakage. Verify system pressure matches this rating.

2.Medium Compatibility Check

Confirm fluid/gas type aligns with specifications (e.g., no corrosive/flammable liquids beyond water/LPG).

3.Temperature Constraints

Avoid environments below -10°C (risk of seal brittleness) or above 80°C (degradation risk).

4.Thread Integrity

Use ISO 228-compliant fittings only. Apply thread sealant (gas-rated for gas applications; PTFE for water).

5.Installation Orientation

Install with flow direction aligned with valve arrow (if marked). Avoid inverted/pressure-reverse mounting.

6.Leak Testing Mandatory

Pressure-test with soap solution or gas detector post-installation. Never use open flames.

7.Exclusion for High-Pressure Systems

Prohibited for:

Standard LPG cylinder valves (>0.8 MPa),

Natural gas mains (>5 kPa),

Compressed air systems (>1 bar).

Safety and Compliance Instructions for Selecting Gas Valves

- Certification: Ensure valve carries regional safety marks (e.g., CE, AGA, or GB for target markets).

- Professional Installation: Gas systems require licensed technicians – DIY is illegal and hazardous.

- Material Warning: Verify body/seal materials (e.g., brass/EPDM) resist specific media (e.g., sulfur in man-made gas).

Our advantages

1). Over 20 Years' Experience in production

2). Accept OEM Order

3). ISO9001 approved

4). We use All New raw material in products

5). Sufficient products with complete specifications for your choice

We Will Be Your Better Choice!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!